5000 LITER (1300 gallon) Milk refrigerated container

Product Classification:

Milk Storage Tanks

Product Summary:

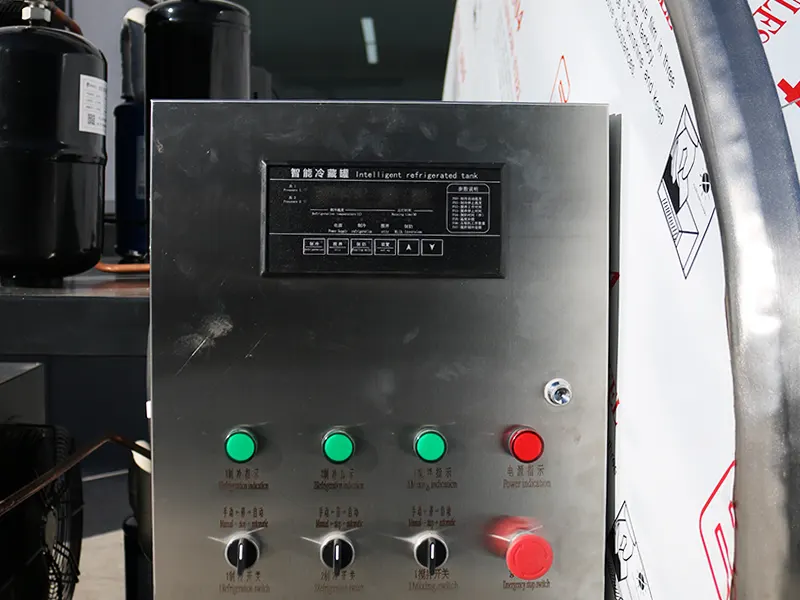

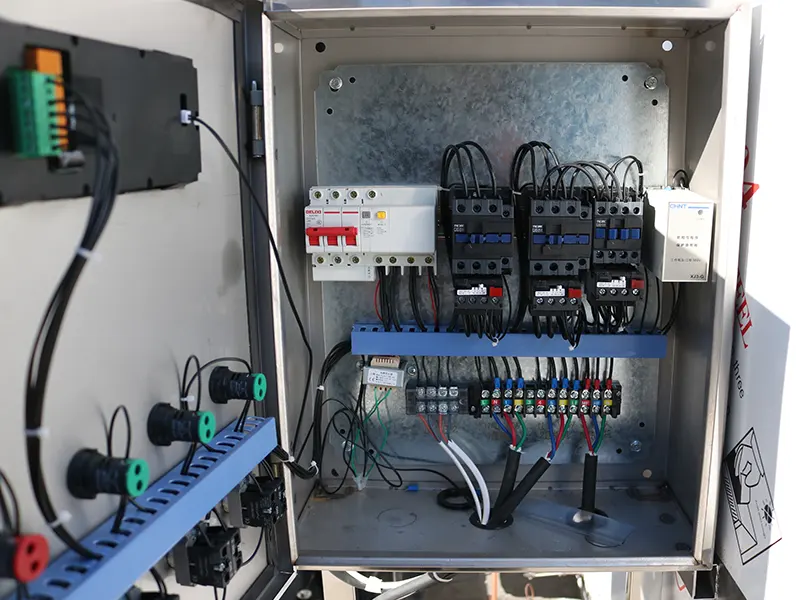

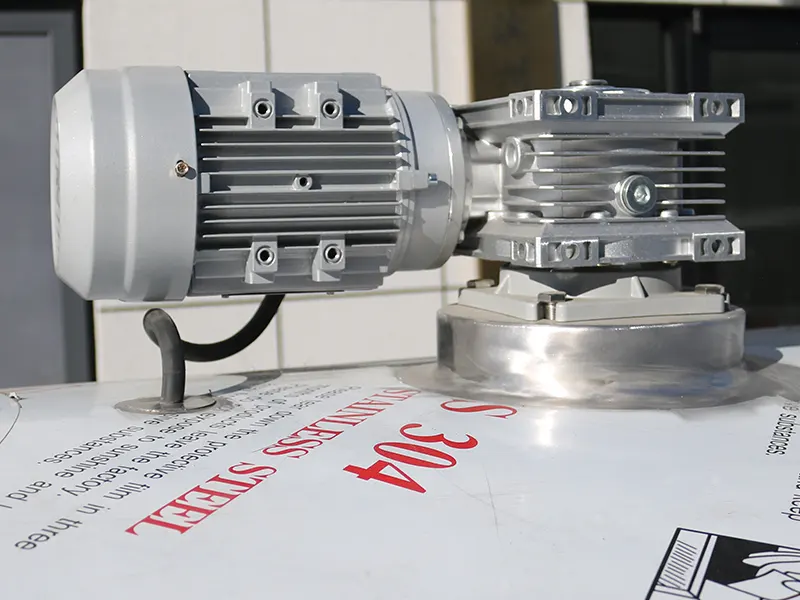

The Refrigeration Unit and the tank are composed of two major parts. The tank bodyadopts SUS304-2B food grade stainless steel material, the insulation layer adoptspolyurethane integral foaming technology, the compressor adopts the international advancedflexible scroll compressor, the optional automatic cleaning device and the electronic meteringdevice, and the tank body adopts SUS304-2B food grade stainless steel material TheIndependent Computer Control System makes the equipment in the intelligent automaticworking state.

keywords:

5T Milk refrigerated container parameter

5000 LITER (1300 gallon) Milk refrigerated container

The Refrigeration Unit and the tank are composed of two major parts. The tank bodyadopts SUS304-2B food grade stainless steel material, the insulation layer adoptspolyurethane integral foaming technology, the compressor adopts the international advancedflexible scroll compressor, the optional automatic cleaning device and the electronic meteringdevice, and the tank body adopts SUS304-2B food grade stainless steel material TheIndependent Computer Control System makes the equipment in the intelligent automaticworking state. The product has the advantages of fast refrigeration speed, high efficiency, goodheat preservation performance, low noise, reliable work, simple operation, long service life, noneed for siteinstallation and so on.

The use of the U. S. corn compressor, through the evaporator, condenser withscientific matching, can make milk from 35 degrees to 4 degrees of time s2 hoursInternal and external use of 304 food-grade stainless steel, to ensure food safety.Inner liner clad plate by laser welding, higher strength, no internal leakage, easy toclean, CIP automatic cleaning, cleaning pipeline for 304 stainless steel, no deadangle cleaningCIP automatic cleaning, cleaning pipeline for 304 STAINLESS STEELno dead corner cleaning.

| Project | Parameter | |

| Appearance | Horizontal elliptical | |

| Material quality | Food grade stainless steel | |

| Inner liner:2.5mm outer wall2.0mm | ||

| Cooling method | Direct cooling | |

| Effective capacity (L) | 25 | |

| Waximum capacity (L) | 304 | |

| Evaporator | Heat transfer area (㎡) | 450 |

| Materlal quality | 50 | |

| Observation hole diameter(mm) | 3760*2200*2100 | |

| Milk outlet diameter (mm) | Hard polyurethane,80mm | |

| Extemal dimensions (length *width * height) mm | GB/T10942-2001 | |

| Imsulafion material andthickness (mm) | GB/T10942-2001 | |

| Thermal insulationperformance | 5Pcompressor*2 | |

| Cooling time | R22 | |

| Compressor | Brand and model | 9 |

| Type of refrigerant | Pressure controller protection | |

| Compressor midpoint protection | ||

| Overcurrent protection | ||

| Phase sequence protection | ||

| Total power (Wk) | 0.55*1 | |

| Compressor protection device | 36 | |

| Mixer | Power (kW) | 630*150 |

| Revolution (rmin) | 32 | |

| Mixing blade size (mm) | Manual/Automatic | |

| Control mode | 2 set | |

| Clean | Number of cleaning nozzles | 380V |

| Source | Main power supply | China |

| Control power supply | Digital display(00.0℃) | |

| Control Box | Origin and brand | 0-99℃ |

| Temperature representationmethod | 0-8℃ | |

| Temperature display range | ±0.5℃ | |

Packaging

Packaging

Packing and shipping

Packing

Production workshop

Production workshop

Production workshop

Production workshop

Previous

6000 LITER (1600 gallon)Milk refrigerated container

Get a free product quote

Guess you might like